Making small screws might be of my favorite things to do. The jack plane project has four different brass screws that have to be made, this post is about the front knob screws. These screws are the longest of the bunch and have a 1-72 pitch. I turn all my screws from 360 brass on a Sherline lathe, equipped with a threading attachment.

Single point turning batches of tiny screws might sound crazy, but I have yet to come up with a better way to achieve the quality I desire. I have tried making them with a threading die and also tried buying them, both fell short of tolerance.

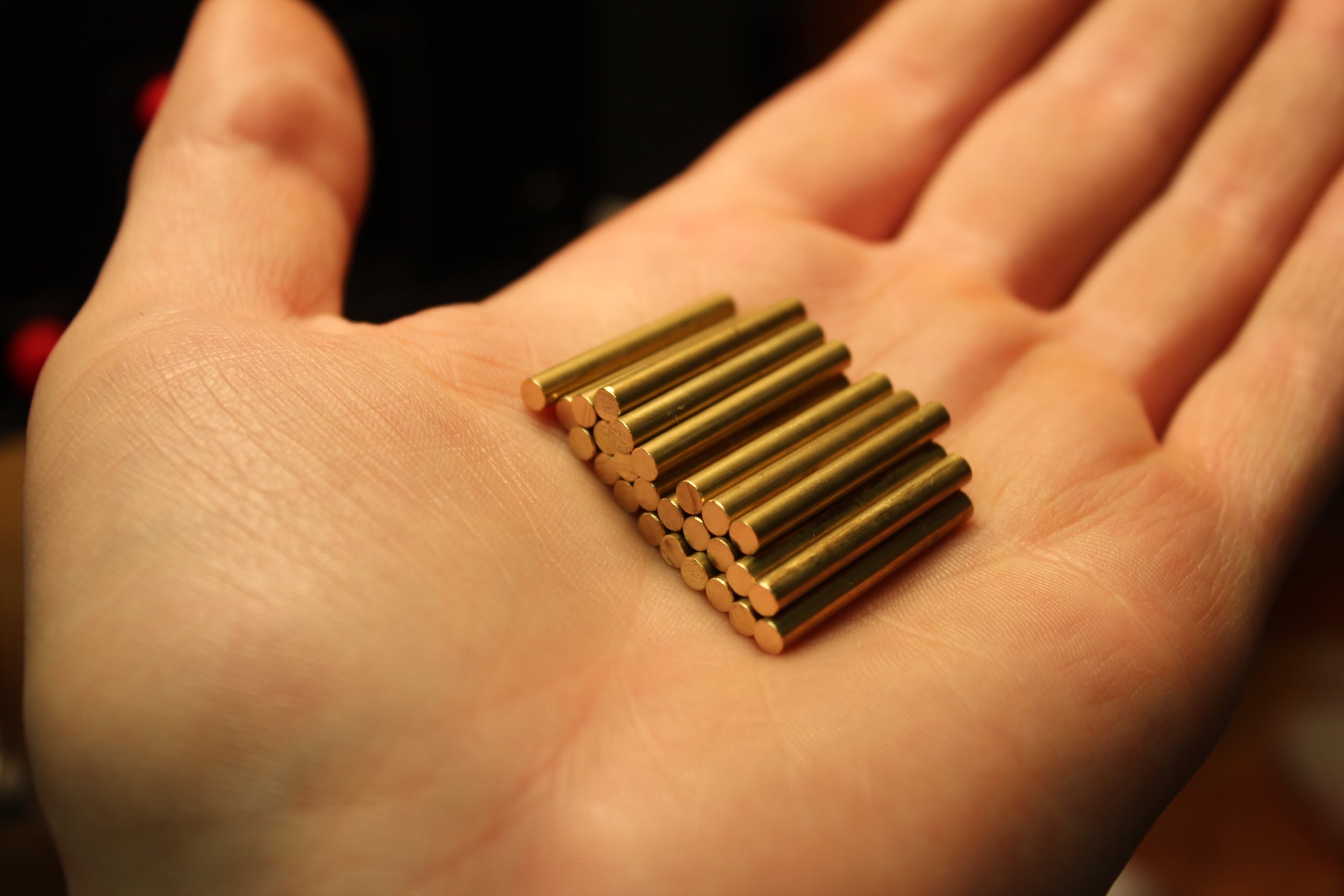

I started with pieces of 1/8" stock cut to the length of the screw plus some extra to grab in the collet.

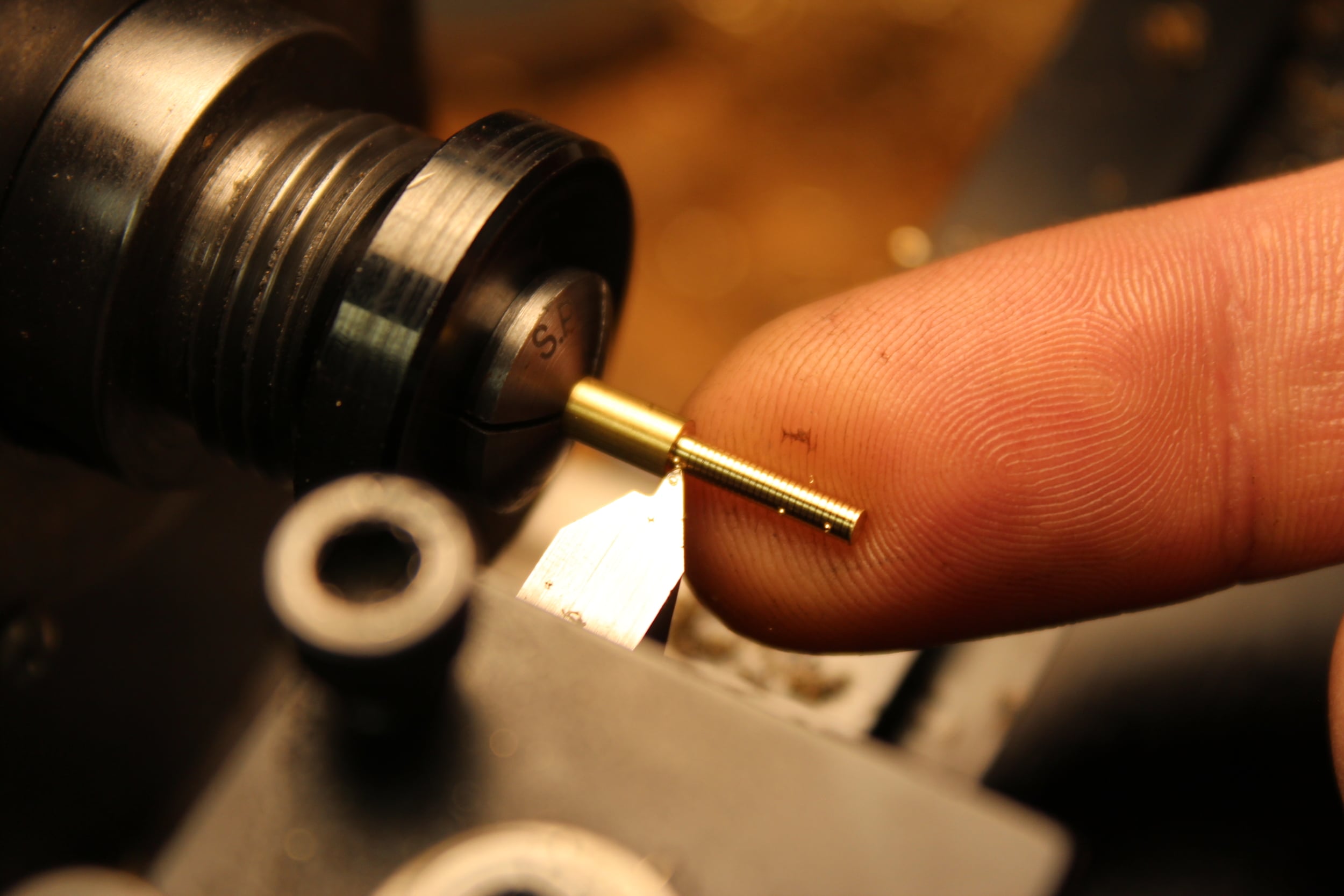

Since the screws are so long, deflection becomes an issue with turning. These screws do not need threads the entire length because a majority of it is in the knob. If I were to turn down the diameter the whole length of this screw, it would deflect too much when it came time to thread. To solve that, I started by turning down just the threaded part to final threading diameter (.073") I set the digital readout zero to accuracy repeat the same size blank.

Pop a blank in the collet and face it off. Set Z axis zero on the face. Move cross slide to zero. Turn down to length, stopping when Z readout says .3". Chamfer the end with super fine file.

Repeat.

With the blanks turned down, the lathe is converted to threading mode. Turning screws on the Sherline is a hand crank operation, no motor. I leave the threading attachment hanging on the machine so I just have to remove the motor, raise up the treading gears, and put the hand wheel on. It usually has the 72 or 80 tpi gear set on, the difference being only one gear.

I ground the threading cutter from a HSS blank with a side relief for getting close to a shoulder. The cutter has zero rake to reduce chatter, and all sides are honed sharp.

The thread is cut in multiple passes. The first being only .003" deep. I use the digital readouts to keep track of depth. The cutter is set to depth, cranked down the screw, backed out, cranked back to the start. This is repeated over a few times, advancing the cutter in about .002" each pass. Once the readouts show me I am to depth, I check it with a nut.

I looked through the stereo scope for the first few screws so I could see the thread formation better, as well as deflection. Under the scope I could see that the first half of the screw would deflect a bit when the cutter was almost at full depth. I ran two passes at final depth to make sure the first half was the same.

Thread cut to full depth.

Testing the thread with a nut before it is removed from the lathe.

With the ends threaded, I inked the remaining stock to scribe a line for final length. I ground a cutter to allow me to cut down the diameter and form the bottom of the screw head at the same time. It has a small flat at the tip. I spend extra time making sure the cutting edge is sharp as can be, and set precisely on center. I am shooting for the best surface finish possible because going back with abrasives would be bad news. Even though only the head of this screw will ever be seen, I sleep better knowing the whole thing has a nice surface finish. Once all the screws were turned down, I switched to a parting tool and cut them off their shank.

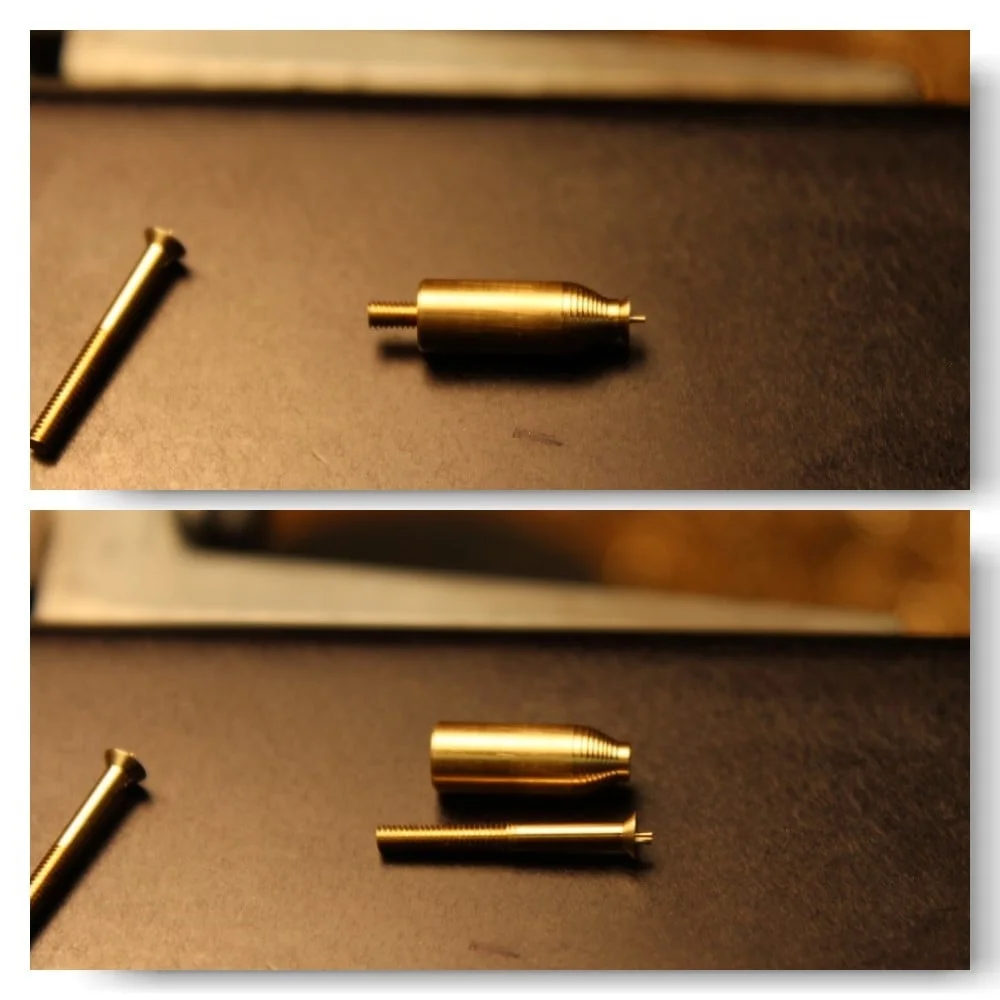

With the screws free from their shank, I had to make a holder so I could work on the top of the head. I have holders for shorter screws already made, but this screw is special because the threads do not go all the way up.

The screw holder is 3/16" stock drilled and threaded 1/-72 through. I then drilled the majority of the threads out for clearance, leaving about 1/8" of threads at the bottom. I then chamfered the edge of the hole so the screw head would seat in. I made the holder short so the threads would come though the back. I need this so I can remove the screw from the holder, because at this point it has no slot to grab.

With the holder done, I turned the screw heads to final diameter and faced off the stud left from parting.

Screw holder for facing the head.

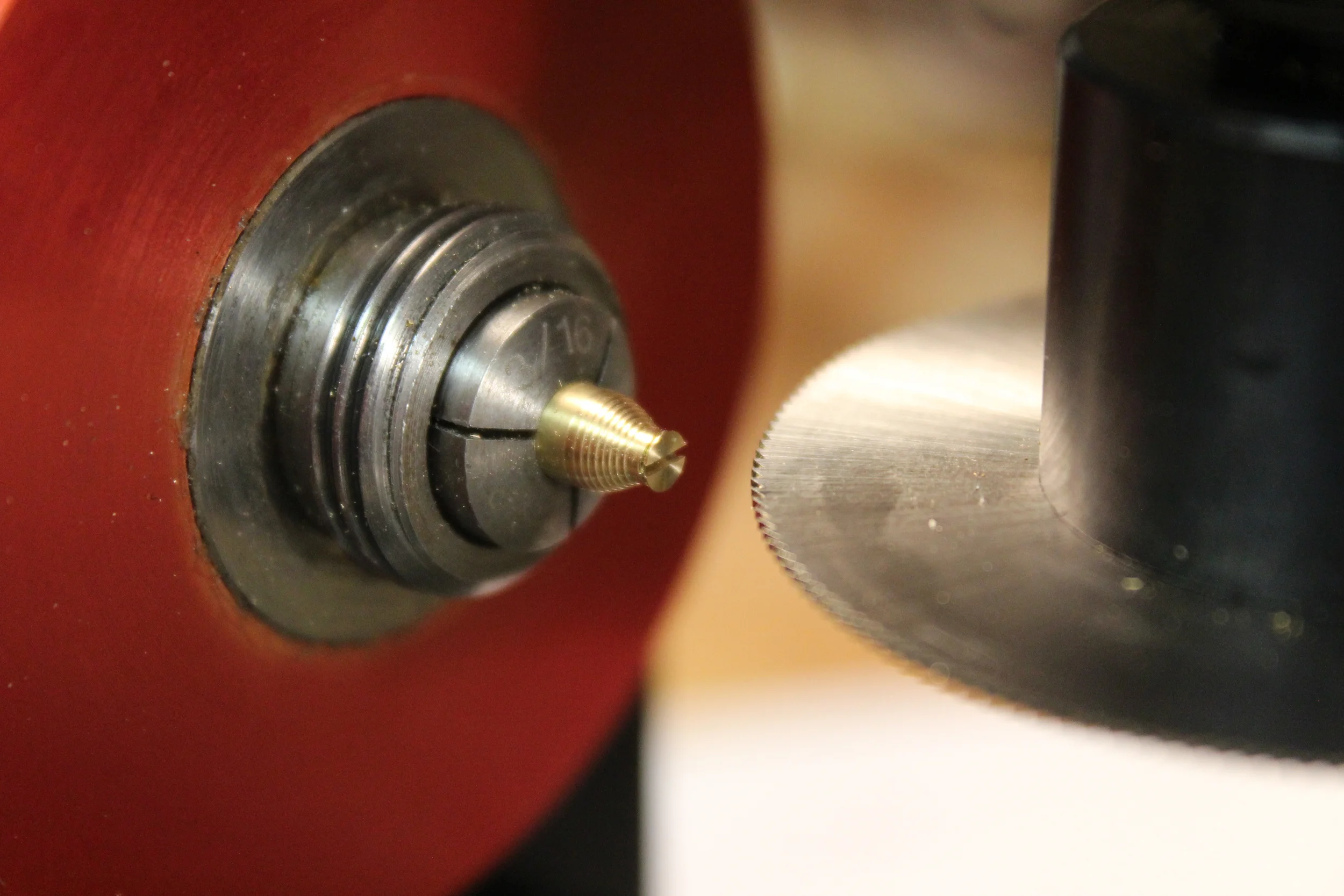

Now to make the these screws functional I had to cut the head slots. I used a .020" slitting saw on the mill. I put the same holder mentioned previously in a indexing head. I did some tests on scrap to make sure the cutter was super centered. One pass per screw, this operation goes quickly. After the screws were slit, I went under the stereo scope and removed the bur left behind from slitting with a tiny file. Screws done.

Finished screws