The adjustable mouth on the miniature planes seemed like a fantasy when the idea was first conceived. I convinced myself it was possible and worth the crazy amount of time required to make it happen. It would kill me to answer "No" to the question "Does it have an adjustable mouth?"

To make the master casting pattern, I measured and scaled down the dimensions of the full scale mouth piece. I then added to the dimensions that would be machined surfaces, I also took into account the shrinkage from molding and casting. I used blue machinable wax to make the pattern. I milled the pattern and pockets on the Sherline mill, then melted a few drops into the center for where the threaded boss would be.

I neglected to take pictures of the molding and casting process, but it was done the same way as the other parts. RTV rubber mold, wax injected multiples, and investment cast white bronze. Once cast, they were glass bead blasted and inspected for casting flaws. A few did not make the cut, but I made extra. The extras were used as practice pieces for the machine setups.

Adjustable mouth wax tree.

Adjustable mouth castings after bead blast.

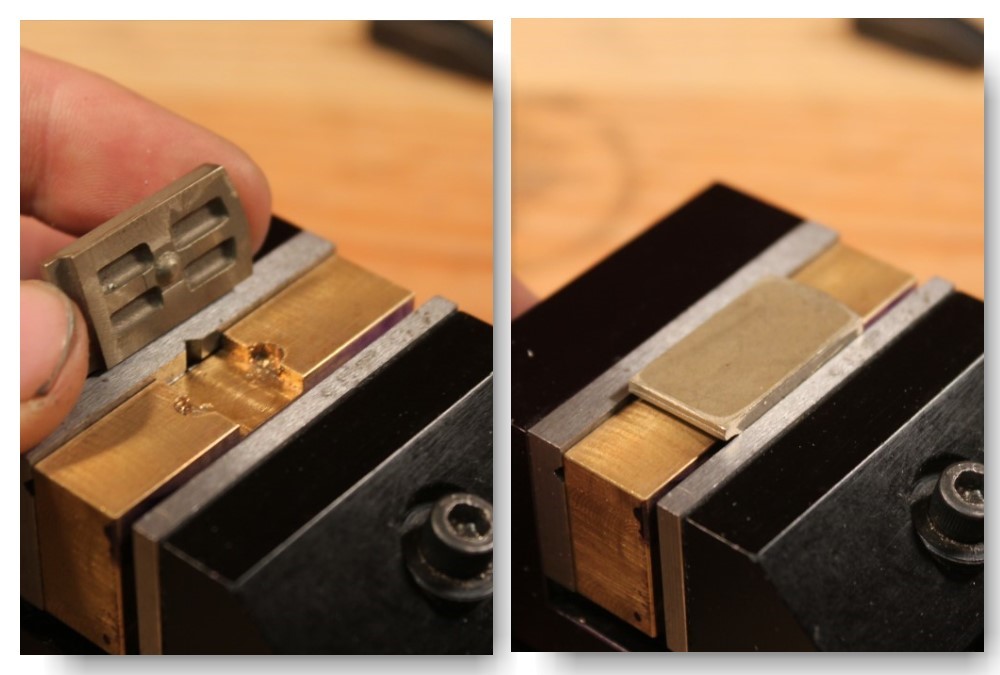

Distortions occur in the process of injecting wax's and casting them. The distortions are very minimal but noticeable with measuring tools. Before these parts could be put securely in the mill vise, they needed a flat side for reference. With sand paper on a lapping plate I lapped the bottoms of the castings until there was enough flat for it to sit without rocking. I then made a brass parallel to put in the vise that would hold the casting at the right height for machining. The parallel has a notch taken out of the middle so the casting could be placed upside down without the bump for the threaded boss causing a problem. I also made a jig to hold it for milling the sides. It has a pocket so the boss has clearance.

Side milling jig.

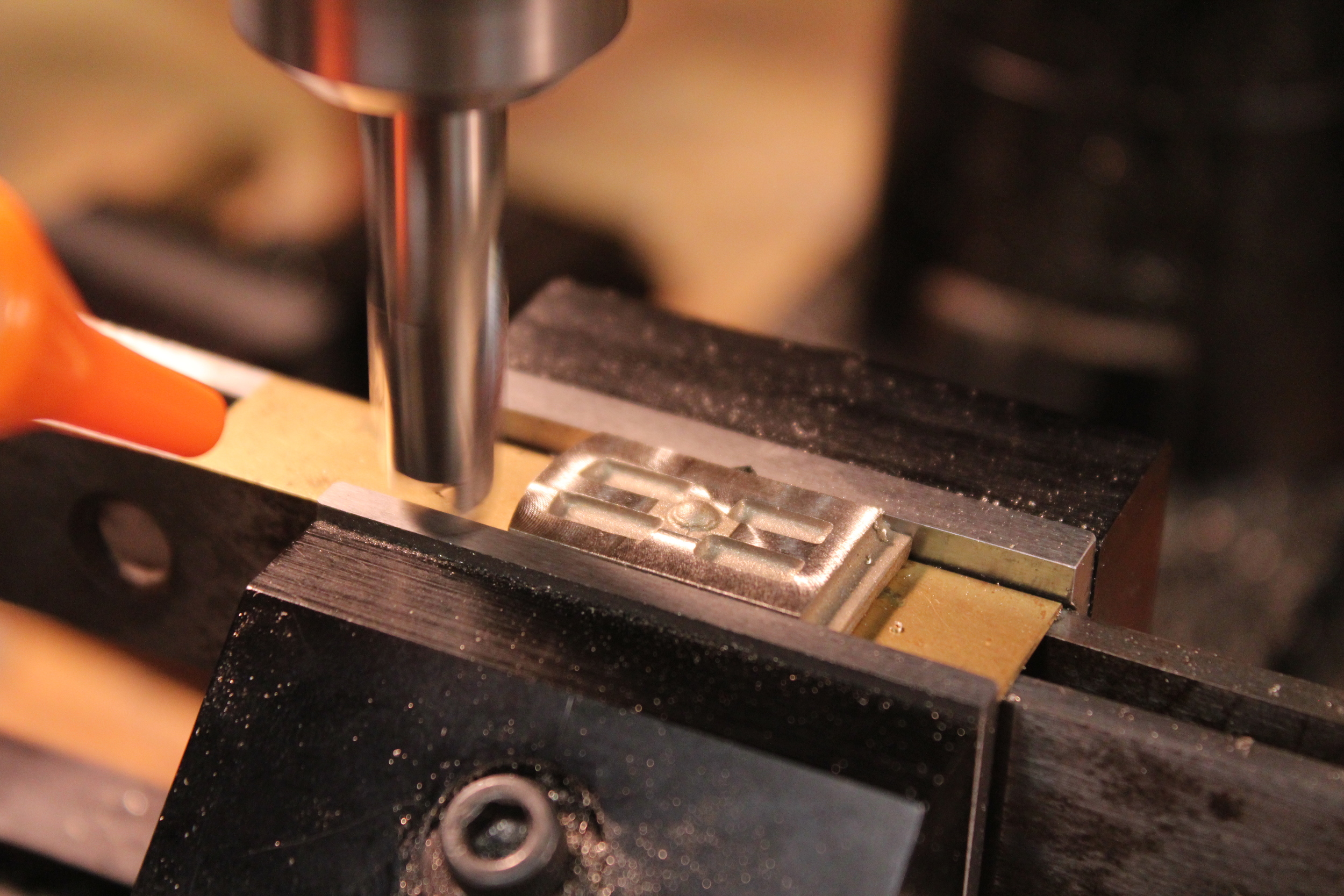

The picture below shows the first machining operation. I am using a 3/8" end mill to skim some material off the top. All I had to accomplish with this first operation was establishing a flat plane on the top surface that I would use as a reference for all the other sides.

Next, I turned the parts over and skim cut the bottoms to make them parallel to the tops.

Establishing a flat on the part.

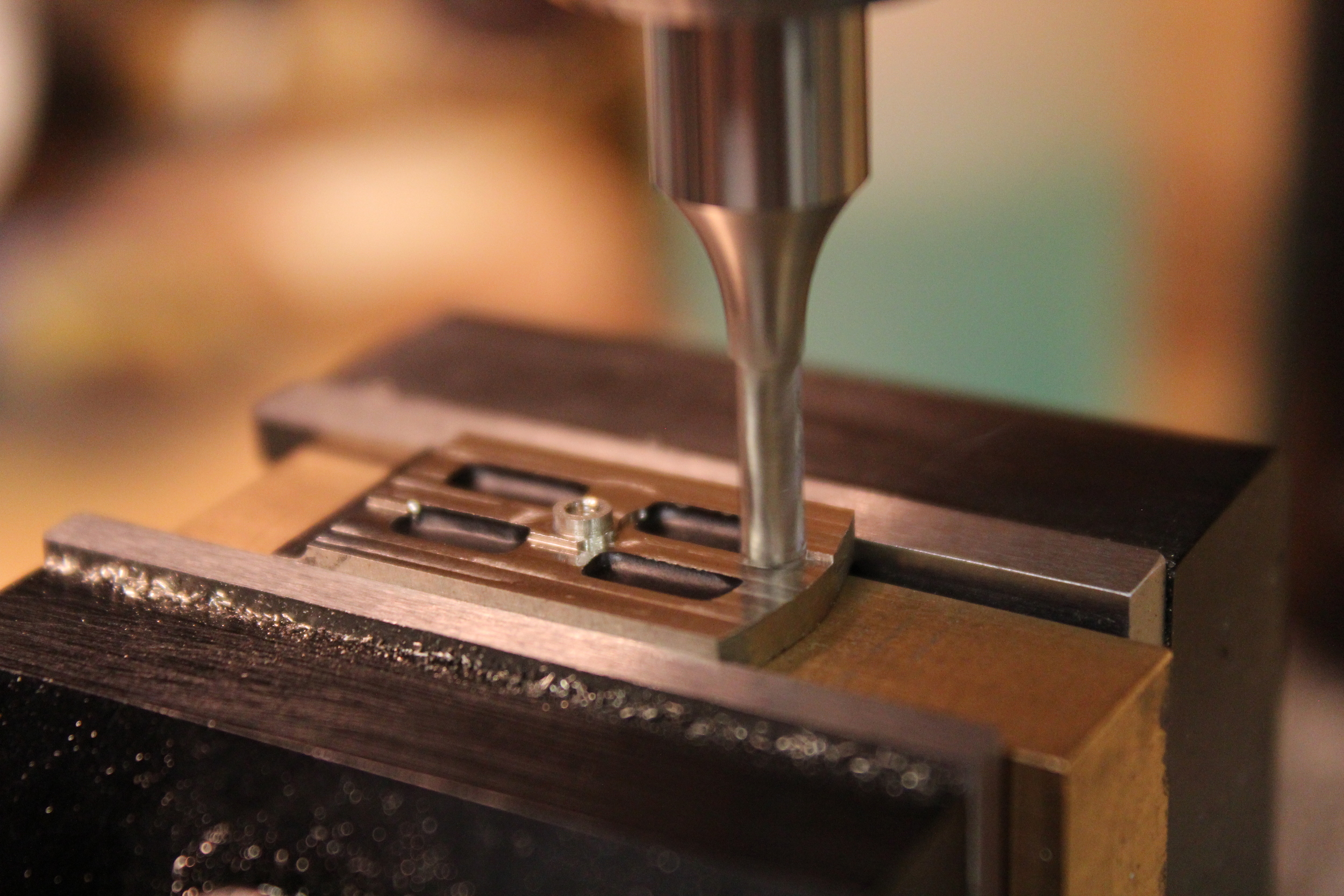

The adjustable mouths have a round boss with a tapped hole for the front knobs to attach to. Although most of the machining on these planes is done manually, I decided to use CNC for this operation. I programmed the tool path to use the center of the threaded hole as a zero point. I did this so I could manually drill/tap the hole then put in the end mill and start the CNC without loosing center. The cam software I am using (Vectric cut2D) does not allow you to choose your plunge points, so I made the cut area longer than needed so it would do most of the plunging off the part and move in.

The tapped hole is a 1-72 thread.

Simulated tool path.

I painted the pockets on the mouthpieces before I milled the tops. It seemed like a good way to achieve crispy paint edges without delicate masking or single hair brushing.

Running the CNC program.

Test part

finished mouth pieces

I made some extra because I plan on messing a few up fitting them to the soles. The sides and bottom surfaces are left alone at this point, they will be worked down to fit the pocket I mill for them in the planes soles. Next post I will talk about machining the soles.